材料試験と調査

Rimkus Materials Testing and Investigationチームは、材料故障解析、腐食調査、溶接エンジニアリングを専門としています。また、さまざまな専門的な材料試験、分析、およびコンサルティングサービスも提供しています。

包括的な故障解析を行うことで、材料故障の根本原因を特定し、冶金学的問題を解決し、将来の再発を防ぐための推奨事項を立てることができます。当社の材料専門家は、高度な分析機器と技術を使用して、試験結果を解釈し、クライアントに詳細な行動計画を提供することができます。

専門スタッフは、欠陥調査、熱処理プロセス、リバースエンジニアリング、コーティングとメッキ、ベンダーの資格、材料の選択など、材料工学の他の多くの分野も専門としています。

世界中の企業や業界が、Rimkus Materials Testing and Investigationの専門スタッフに頼って、迅速かつ正確な材料試験結果を提供しています。これらの業界には、モータースポーツ、自動車製造、配管(水システム)、海洋、化学および医薬品製造、発電およびユーティリティ、熱交換器、ボイラーなどがあります。

材料試験および調査ラボサービスの詳細については、以下をご覧いただくか、(704)663-5108または [email protected] に直接お問い合わせください。

また、Rimkusは、保険や訴訟に関連する重要な問題について、経験豊富なコンサルタントの専任チームを擁しています。詳細については 、材料科学およびエンジニアリングのページ をご覧ください。

当社の材料試験および調査サービス

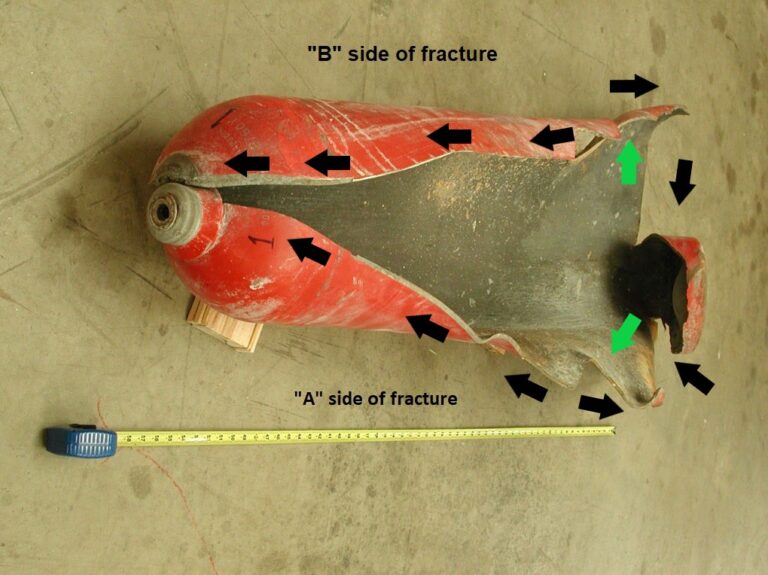

故障解析は、製品の故障につながる原因や一連の事象を特定するために、部品を系統的に検査、試験、分析することによって行われる。この専門的なテストは、発見された結果によって大きく異なります。

このプロセスには通常、以下のステップが含まれる:

- コンポーネント、そのアプリケーション、およびその履歴に関する情報の収集

- 詳細な目視検査

- コンポーネントと視覚的証拠の写真ドキュメンテーション

- 非破壊検査

- 低倍率立体視鏡検査または3Dイメージング

- 高倍率走査型電子顕微鏡(SEM)検査

- 元素分析分光/SEM

- 金属組織微量分析のためのサンプルの切片化

- メタログラフィー

- 硬さ試験

- 化学分析

- 機械的試験

- 詳細なエビデンスとデータレビュー

- 専門的な結論と意見の定式化

- 私たちの調査結果と推奨事項の相互運用性レポート

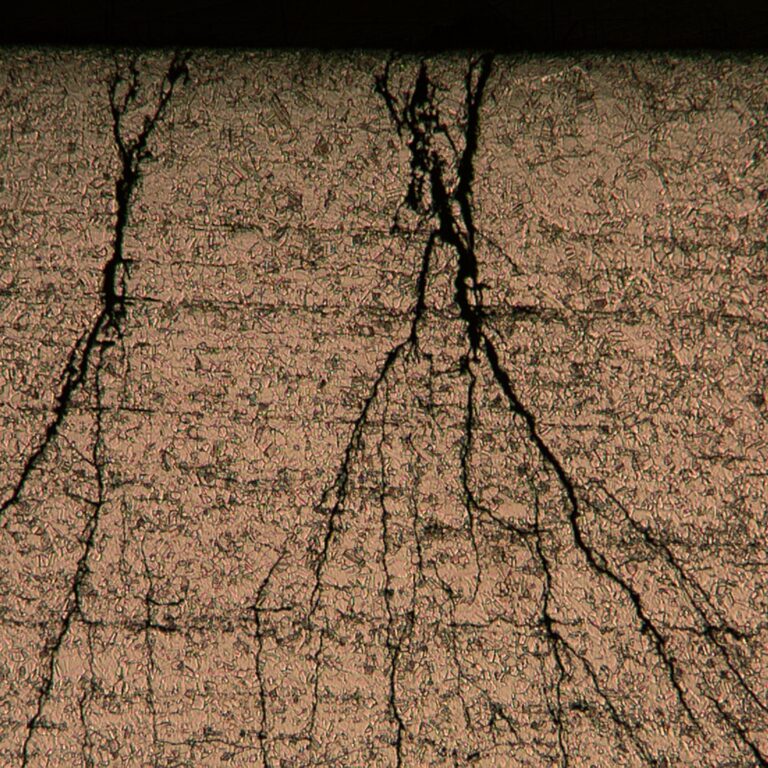

腐食は、材料の劣化をもたらす化学反応現象であり、深刻な、あるいは致命的な故障につながる可能性がある。腐食調査エンジニアリングとは、腐食故障のサンプルを収集し、それを分析して腐食の原因(根本原因)と深刻度を特定するプロセスです。これらの分析から、腐食の修復と防止に関する専門家の意見と推奨を提供します。

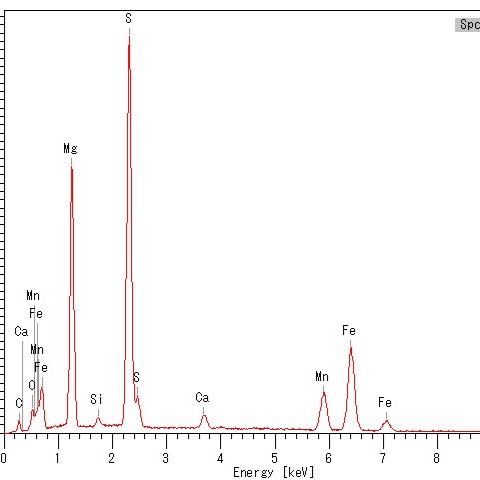

リムクスの材料試験・調査チームは、腐食調査エンジニアリングと腐食メカニズムを特定するための分析技術を専門としています。腐食の再発を防ぐため、特定の用途や環境に対して、より耐食性の高い合金やコーティングを推奨する専門知識を持っています。当社のエネルギー分散型X線分光法(EDS)システムは、腐食堆積物を分析し、腐食剤を特定することができます。また、特定の環境に対する材料やコーティングの適合性を判断するための加速塩霧腐食試験やその他の腐食試験に関する専門知識と能力も有しています。

機械や構造物の用途で健全な溶接を成功させるには、かなりの量の冶金工学が必要である。

当社は、米国溶接協会(AWS)や米国機械工学会(ASME)など、さまざまな工業規格への準拠を保証する溶接士および溶接手順資格試験を提供することができます。

当社では、生産開始前に溶接部の健全性、靭性、脆性、硬度、その他の特性を評価するための溶接試験を実施しています。私たちのチームはまた、現場で溶接部の破壊や劣化の根本原因を特定するため、溶接不良を頻繁に調査しています。

溶接士および溶接手順資格:

- ベンド試験

- シャルピー衝撃(CVN)試験

- 蛍光染料浸透剤

- 目視検査

- マクロエッチング試験

- 引張強度

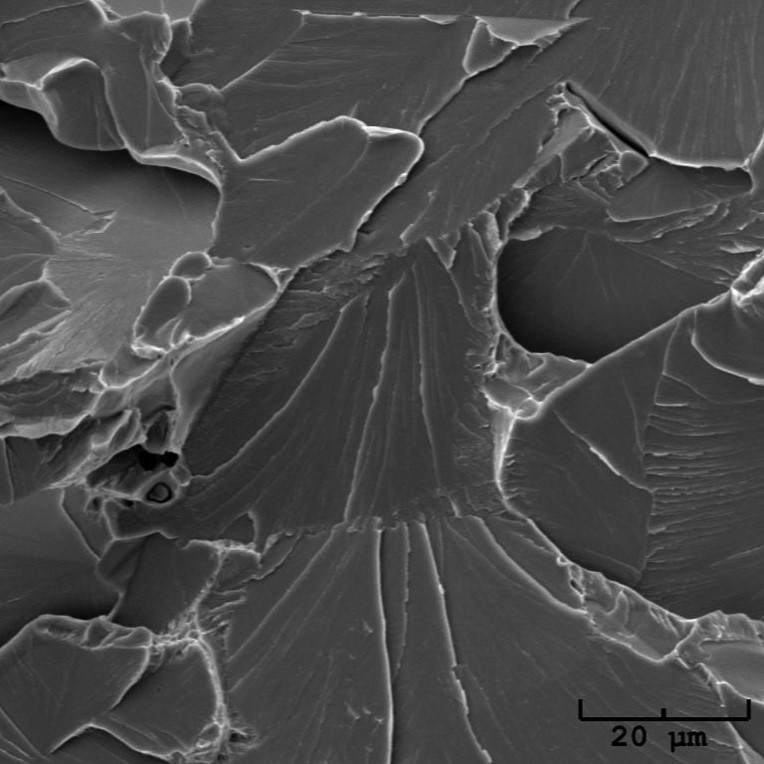

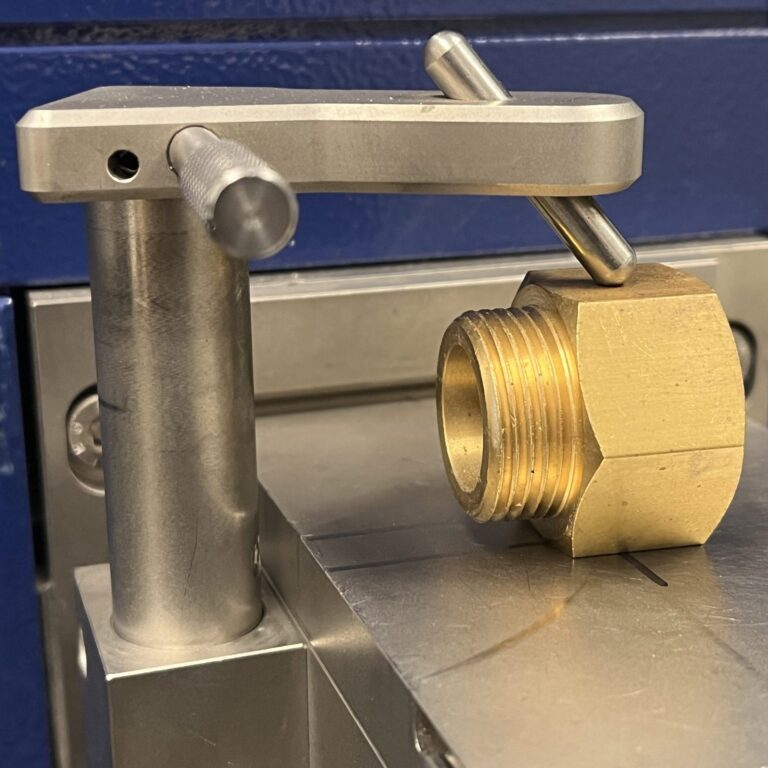

当社の走査型電子顕微鏡(SEM)は、エネルギー分散型X線分光計(EDS)を加え、通常5倍から20,000倍の倍率でサンプルを検査・分析することができます。最先端の走査型電子顕微鏡を使用することで、当社の専門家は、微細構造や破断面から腐食生成物、孔食、材料内の不純物まで、あらゆる分析を行うことができます。

倍率を上げると、破砕面のトポグラフィーは法外な量の情報を明らかにすることができる:

- 応力のタイプ(引張、せん断、ねじり)

- 破壊モード(延性、脆性、疲労、過負荷)

- 破壊伝播の方向

- 骨折開始の領域とメカニズム

- 微細構造内の汚染

- 腐食生成物および堆積物の元素分析

- 非常に小さな部品の元素組成

- 故障の原因となる製造または修理関連の要因

- 障害の原因に関連するその他の要因

Rimkus Materials Testing and Investigationラボには、材料分析と腐食調査に特化した2つの商用SEM/EDSシステムがあります。

Rimkus材料試験および調査の専門家は、次のようなさまざまな非破壊検査技術を利用しています。

- エネルギー分散型分光法(EDS)

- 走査型電子顕微鏡(SEM)

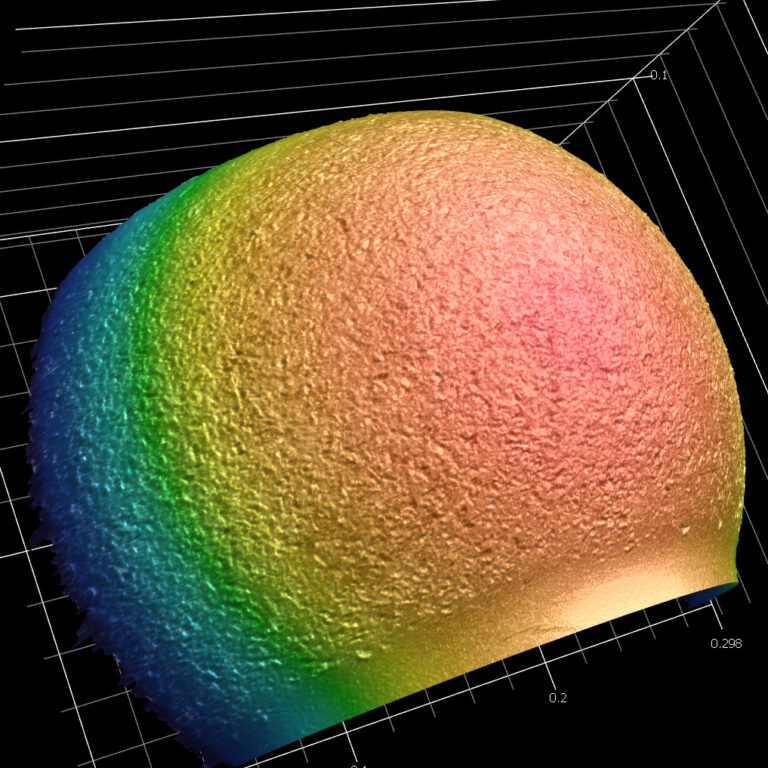

- 高解像度の3D表面プロファイル

- 3Dプロファイル測定

- 表面仕上げ/粗さ

- 液体浸透探傷試験(PT)

- 表面に開いた材料欠陥を検出したり、開いた表面の亀裂を検出したりするために、さまざまなタイプの液体PT法が利用されています。赤色染料または蛍光浸透剤、ならびに様々なタイプの湿潤および乾燥現像剤が利用されます。

- 磁粉探傷検査(MPI)

- 強磁性体の表面および浅い表面下の不連続性を検出するプロセス

- ポータブル硬度

- ロックウェル、ブリネル、リーブ

- 目視検査および低倍率検査

- ポータブル蛍光X線(XRF)分光計

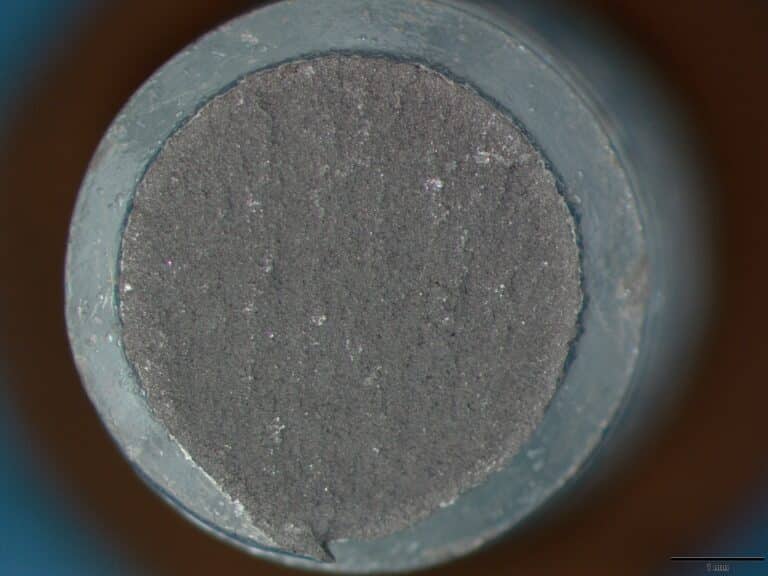

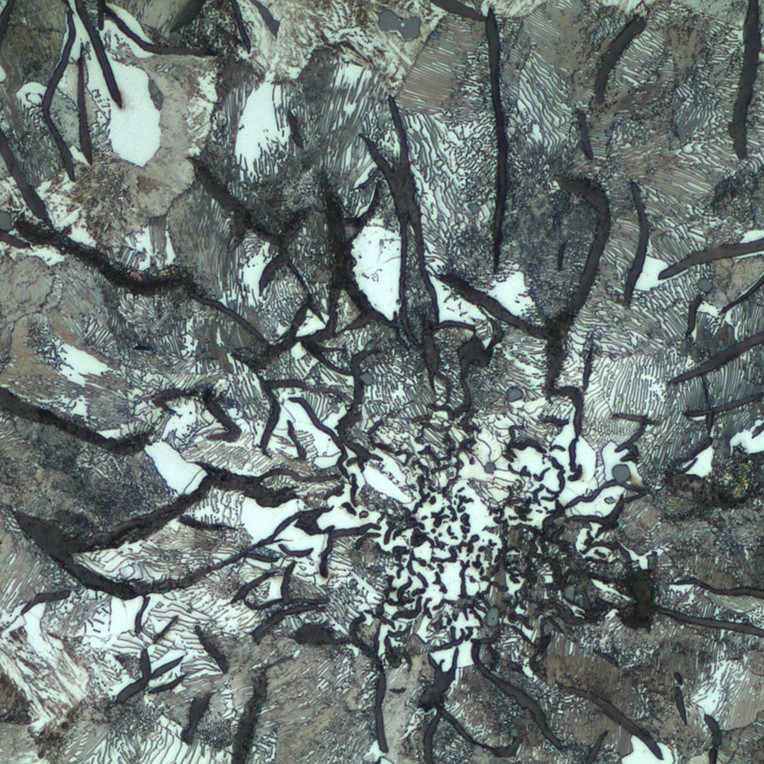

金属組織学は金属材料の微細構造を研究する学問である。材料の特性や特定の用途における性能は、その微細構造によって決まります。リムクスは金属組織検査プロセスにおいて、数多くの種類と倍率の高解像度光学顕微鏡とデジタル顕微鏡を使用しています。

断面試料の微細構造の分析は、材料特性、破壊伝播、腐食孔食の形態、熱処理、メッキとコーティングの品質と厚さ、粒度、過熱損傷、材料汚染、欠陥特性、溶接品質、製造設計の欠陥、欠陥メカニズムの決定に役立つ。

リムクスの材料試験・調査チームは、試験片の切り出しや取り付けから、研削・研磨の段階を経て、試験材料の適切な選択とエッチング技術に至るまで、金属組織学的な試料作製手順/プロセスに関する高度な訓練と知識を持っています。当社の専門試験所スタッフは、冶金学的試料の準備技術とそれに続く解釈を全国のお客様に提供するために頼りにされています。

製造工程では、いくつかの段階で欠陥が発生する可能性があります。リムクスの材料試験・調査の専門家は、必要な高度な分析機器、専門的なトレーニング、経験に支えられ、欠陥が発生した特定の加工工程を特定するための高度な欠陥調査を行います。リムクスの専門家は結果を解釈するだけでなく、将来の欠陥を防止するための提案も行います。

私たちのチームは、他の材料試験方法とともに高品質の欠陥調査を提供することで、製造工程で発生した欠陥や瑕疵が原因で製品が故障したのか、あるいは通常または異常な使用中に故障が発生したのかを特定することができます。

走査型電子顕微鏡(SEM)とエネルギー分散型X線分光器(EDS)を併用することで、材料の化学的特性/元素分析を特定できる高度な分析技術です。EDS分析では、微細な粒子から微小な粒子、または試料表面の大きな領域の元素組成を特定することができます。

SEM検査では、走査型電子顕微鏡に取り付けたEDSを用いて、目的の場所、堆積物、または領域を分析する。EDS微量分析は、試料を走査する集束電子ビームによって発生する信号のエネルギーと強度を測定することによって行われます。

エレメンタル・ドット・マップ

元素マッピングは、試料表面の元素分布を測定します。通常、この手法では、走査型電子ビームとEDS検出器を格子状に組み合わせて、1視野の分析を行い、マップを作成します。この分析は、汚染、コーティング/メッキ層、溶接中の拡散、腐食生成物を特定する場合に特に有用です。

リムクスの専門家は、適用される規格や仕様に対する材料の適合性を判定するための機械試験において豊富な経験を有しています。リムクスは機械試験の方法について豊富な知識を持ち、試験結果の解釈にも熟練しています。

私たちのチームは、品質保証プログラム、製造エンジニアリングプログラム、故障解析、または材料研究開発の一環として、機械試験や材料試験を実施することができます。試験は、ASTM仕様またはその他の業界標準に準拠して実施することができます。

社内の機械試験装置は、以下の材料試験に使用される:

- ベンド試験

- 引張試験

- 圧縮試験

- CVN(シャルピーVノッチ)試験

- 微小硬さ試験(ヌープ、ビッカース)

- ロックウェル硬度

- ブリネル硬度

リバースエンジニアリングとは、部品の製造に使用された材料や加工を特定・分析し、同一の特性を持つ製品を作る方法です。化学組成、熱処理、コーティングの種類、コーティングの厚さなどの材料特性を決定することにより、リバースエンジニアリングを実現できます。

- 化学分析

- 材料の化学組成の特定

- 金属組織学/微細構造評価

- キャスト

- 鍛造

- 押し出し

- 表面処理(窒化物、浸炭など)

- 熱処理

- 硬さまたは微小硬さトラバース

- ケースの有効深さ

- 微細 構造

- コーティング

- 鍍金

- クラッド

- アルマイト、リン酸塩、化成皮膜など

故障解析や腐食調査の非常に重要な要素は、金属の化学分析です。多目的に使用される化学分析は、製造上の問題を特定し、品質管理要件を満たし、再作成が必要な部品のリバースエンジニアリングに極めて重要です。

材料の化学成分分析と検証は、各コンポーネントや原材料が正しい材料合金の仕様に従って製造されていることを保証します。化学成分分析は、ASTM、SAEなどの適切な業界標準と結果を比較する様々な方法を用いて実施することができます。当社の専門家チームは、鉄、鋼、アルミニウム、銅、ニッケル、亜鉛、チタン、鉛を含む(ただしこれらに限定されない)幅広い材料の合金含有量を日常的に分析しています。

金属の場合、OES(Optical Emission Spectrometry)技術は、電極と分析する材料のサンプルの間に生じる高エネルギーのスパークを利用する。スパークにより、励起された試料表面から元素の化学組成に特徴的な波長の放射が発生する。放射線のスペクトルは異なる元素の線に分離され、各線の強度が測定される。最終的に、これらは存在する各元素の濃度値に正確に変換される。

OESは、固体金属試料の直接化学分析のための参照技術であり続けている。精度、高速性、精密性、安定性、信頼性の比類ない組み合わせにより、高品質の金属製品の製造と検証に不可欠なツールとなっています。

現場での金属組織観察は、使用中の部品を取り外すことが不可能な場合や、部品の大きさによって実験室での分析が不可能な場合に必要とされる(半)非破壊検査である。

様々な複製媒体技術により、当社の専門家は、現場で目的の微細構造の携帯用コピーを作成することができます。複製には、軽く研磨して材料の表面を除去し、次に細かい砥粒で研磨することが含まれます。

表面が適切に研磨され、準備されると、材料の微細構造を明らかにするために、さまざまな酸でエッチングされる。その後、レプリカ媒体を塗布し、硬化させる。複製媒体の硬化が完了したら、試料から剥がされ、私たちの研究室に戻され、さまざまな顕微鏡を使って分析されます。

レプリケーションは、表面仕上げやその他のテスト、形状の複製、腐食孔、ひび割れなど、画像化や測定が必要な表面の複製にも使用できます。

6×11インチの完全自動ステージを備えた高解像度キーエンスVRは、大型サンプルの測定・分析能力を強化します。研究開発から生産、品質管理から故障解析、欠陥調査に至るまで、ほぼすべての産業、エンジニアリングのあらゆる段階で活用できます。

キーエンスVRは、お客様の複雑な問題を理解するために私たちが活用している数多くの先端技術・分析機器のひとつにすぎません。

- 複雑なプロファイルの測定

- キーエンスVRは、任意の2Dまたは3Dオブジェクトまたは表面をスキャンし、任意のタイプの2Dおよび3D表面またはプロファイル測定を提供できます。また、非接触の表面仕上げと粗さの測定、および真の表面平坦性の評価も可能です。

- 表面仕上げと粗さ

- 表面仕上げおよび粗さ試験は、当社のラボで、または高解像度のゼロ収縮複製媒体を使用して現場で実施できます。

- 製品の欠陥とフィットアップ

- ゴム製ガスケットの取り付けが不適切だったのか、それともメーカーから不良品だったのか?ガスケットシートはガスケットの寸法と一致しましたか?キーエンスVRで得られた高解像度の3Dプロファイル計測値を用いて、これらの疑問に答えることができます。

- 製造上の欠陥

- キーエンスVRは、異常な摩耗傷跡、成形ライン、変形、ねじ山の損傷、または腐食孔食のコンポーネント(配管継手など)の評価に使用できます。

- 環境屋根の損傷

- 帯状疱疹への環境雹による損傷は、特徴付けと評価が難しい場合があります。キーエンスVRを使用することで、屋根板の損傷を評価、特徴付け、確認することができます。

- 非破壊分析

- ギアとブッシングの3Dプロファイル測定が、破壊試験なしで可能になりました。これにより、プロジェクトマネージャーは、摩耗パターンを迅速かつ効率的に、高い精度と再現性で評価することができます。

- 射出成形金型の欠陥

- 射出成形金型や金型は不適切に摩耗し、最終製品に欠陥を引き起こす可能性があります。これらの摩耗痕や欠陥を測定して、金型や金型の寸法を特徴付けて特定できるようになりました。

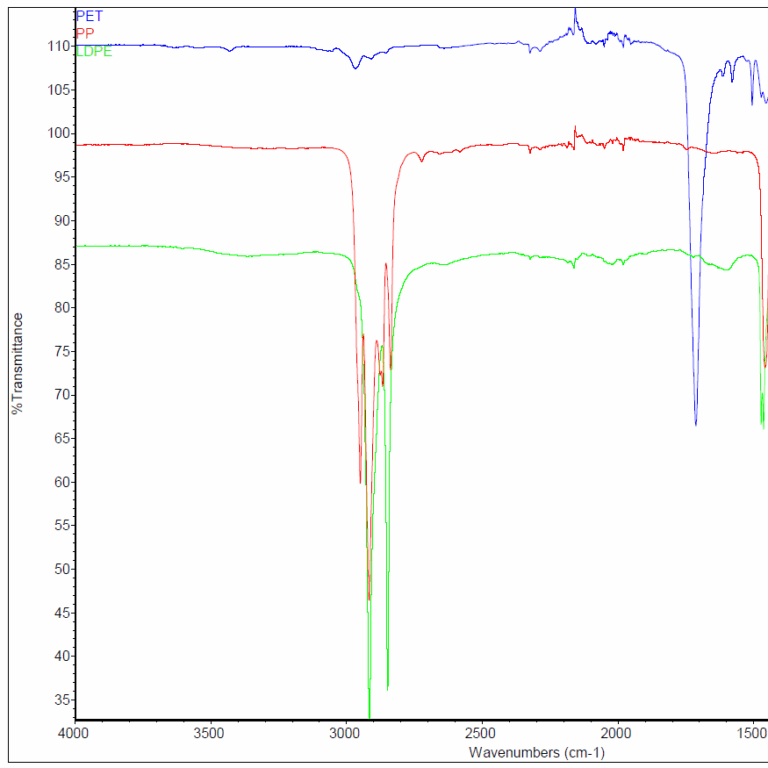

フーリエ変換赤外分光法(FTIR)は、様々な物質の分子組成を同定し、特徴付けるために使用される強力な分析技術です。この方法では、赤外光を利用して試料内の化学結合の固有の振動周波数を検出し、「化学指紋」として機能する特徴的な赤外スペクトルを生成します。FTIRは、非破壊で信頼性が高く、多目的な分析が可能なため、試料の定性および定量評価を可能にし、広く評価されている。

FTIR検査の応用

FTIRスペクトロスコピーは、産業界の様々な用途における材料の理解と最適化に不可欠な詳細な分子情報を提供することができます。正確で迅速な結果を提供する能力により、FTIR検査は研究、開発、品質管理において極めて重要なツールとなっています。主なアプリケーション

- 物質の同定:FTIRは、スペクトルを参照ライブラリーと比較することで、未知の物質を同定することができる。特に、ポリマー、プラスチック、エラストマーの組成分析、複合材料の組成調査、コーティングや薄膜の組成と厚さの評価に役立ちます。

- 品質管理:FTIRは材料の化学組成を特定することで、製品の一貫性と品質の検証に役立ちます。汚染物質を検出し、原材料の純度を確認し、最終製品の配合を確認します。

- 環境分析FTIRは、有害物質の存在を検出することにより、水や土壌などの環境サンプル中の汚染物質や汚染物質を特定するのに役立ちます。

- 医薬品 / 化粧品とパーソナルケアFTIRは製品の配合を評価し、正しい成分組成を確認することで、コンプライアンスと品質保証に貢献します。

- 科学捜査FTIRは、薬物、爆発物、繊維、残留物など、犯罪現場で発見された未知の物質を分析することで、科学捜査に利用することができる。また、塗料、接着剤、その他の材料のような微量証拠の特性評価にも有用です。

- 食品・飲料業界FTIRは食品成分の組成と真正性を確認することができ、不純物の検出や品質基準への準拠を保証するのに役立ちます。

- 毒物学 FTIRは、血液、尿、組織などの生物学的サンプル中の有害物質や汚染物質を同定するための毒物学的分析に使用することができる。FTIR検査は、既知の物質の参照スペクトルと比較するために使用されるスペクトルプロファイルを提供し、有害な化学物質、薬物、環境毒素の検出に役立ちます。