When a contractor installs a fastener, it is expected to perform according to its design and support the engineering of the structure. If the fastener fractures unexpectedly, it is crucial to determine why. Was it due to manufacturing error, improper installation, corrosion, or some other phenomenon, such as hydrogen embrittlement? Fastener failures have the potential to have catastrophic consequences, so identifying the root cause is essential for future reliability and safety.

Hydrogen embrittlement (HE) is a form of stress corrosion cracking (SCC) defined by ASTM International as, “a permanent loss of ductility in a metal caused by hydrogen in combination with stress (either externally applied or induced internally, as residual stress).” This phenomenon is most commonly associated with high-strength fasteners made of carbon and high-strength low-alloy (HSLA) steels. Although not as common, HE can also present in precipitation-hardened stainless steel, titanium, and aluminum alloys. Hydrogen embrittlement is also known as hydrogen-assisted cracking or hydrogen damage.

Embrittled fasteners under stress can fracture suddenly and without warning. HE is often referred to as a “silent killer” of fasteners due to it being very difficult to nearly impossible to detect during non-destructive quality checks of new fasteners.

Hydrogen embrittlement occurs when nascent (atomic) hydrogen diffuses into the solid metals after fabrication. Exposure to nascent hydrogen most often occurs in two forms:

- Environmental Exposure: One byproduct of aqueous corrosion of metal is the liberation of hydrogen from the water during electrochemical corrosion mechanisms, such as oxidation (rusting) of the base material or galvanic corrosion between two dissimilar metals.

- Manufacturing: As a precursor to surface treating fasteners (plating, coating, finishing), fasteners are cleaned using acid pickling baths. Hydrogen is absorbed into the steel and generally requires the fasteners to be baked in a low-hydrogen environment to remove the absorbed hydrogen. Plating or galvanizing the charged fastener will trap the hydrogen in the steel and lead to brittle fracture.

There are three key factors necessary to cause a hydrogen embrittlement failure of fasteners:

- A susceptible material (typically high-strength steel)

- A hydrogen source (from one of two previously described sources)

- Sustained mechanical stress (installation of fasteners)

When the contribution from all three conditions reaches a threshold, brittle fracture is likely to occur. The time to fracture varies depending on the severity of the conditions. The failure can be delayed, sometimes occurring hours, days, or even weeks after the fastener is assembled.

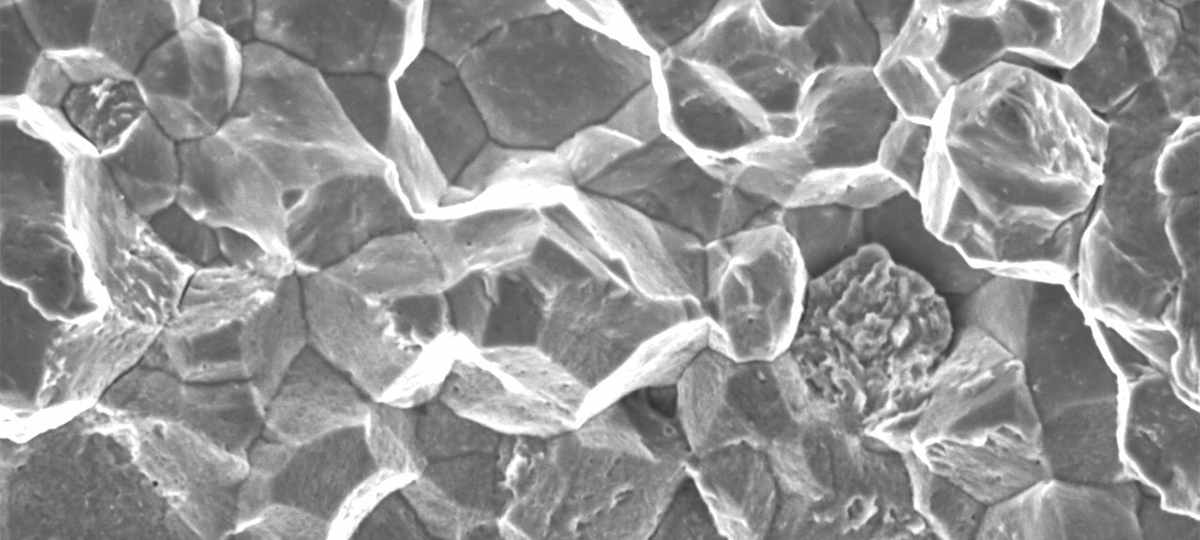

HE failures often have a fracture surface with an intergranular appearance, sometimes described as rock candy.

- Select a material and hardness specification that is not susceptible to HE.

- Avoid electroplating fasteners with a hardness above 39 HRC. (Electroplating processes will generally utilize an acid cleaning/pickling process to prepare the fasteners for the plating.)

- Ensure that proper plating procedures and post-plating baking practices are utilized.

- Use a coating process that does not introduce hydrogen into the material (particularly those that do not utilize acids for cleaning.

- Properly selecting the fastener material/strength for specific service environments can reduce the risk of embrittlement.

A materials lab analysis is always necessary to determine if the fastener failure was due to hydrogen embrittlement. Steel mills, manufacturers, plating companies, distributors, contractors, and end users all rely on the experts at Rimkus Materials Testing and Investigation.

To contact the Lab or submit a project for testing, call 704.663.5108 or email us at [email protected].

|

|

|

|