Background

A 300M ultra-high strength steel transmission input shaft fractured during a NASCAR race after approximately 254 miles. A metallurgical failure analysis was performed by the Rimkus Materials Testing and Investigationopens in a new tab team to evaluate the cause of the fracture.

Services Provided

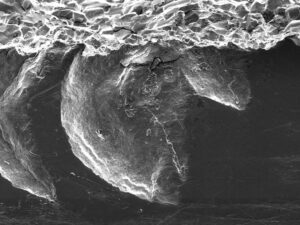

The fractured input shaft was subjected to a series of testing and analytical techniques including visual and stereoscopic examinations, scanning electron microscope (SEM) examinations, metallography/microstructure evaluation, chemical composition analysis, and Rockwell hardness testing.

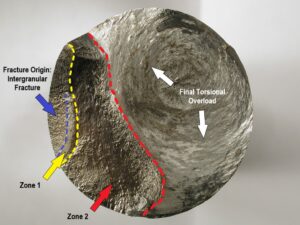

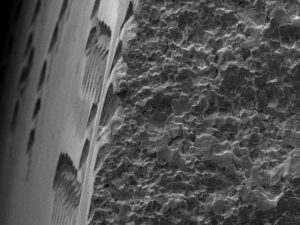

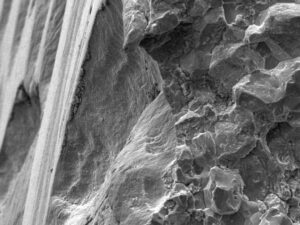

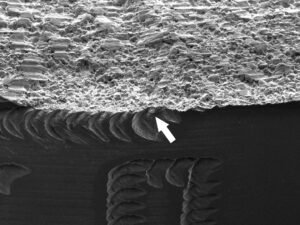

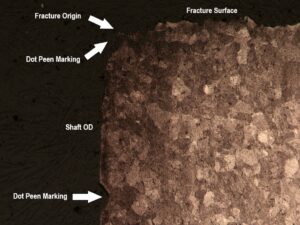

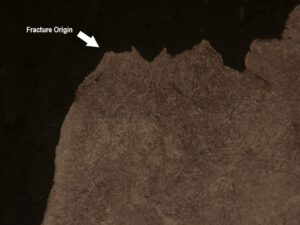

Results of the testing indicate the fracture occurred due to fatigue progression from an intergranular stress crack that initiated at a dot peen identification marking on the shaft. The dot peened engraving creates a high stress concentration in the hard surface (54 Rockwell C – HRC) of the shaft. A shallow zone of intergranular fracture was observed, which initiated at the bottom of the dot peened lettering on the shaft. Prior to the final torsional overload failure of the input shaft, two events of fatigue progression were observed to be covering approximately 33% of the fracture surface. Intergranular cracking at the initiation site indicates a brittle surface condition, which may be an indicator of excessive residual stress on the surface of the shaft.

Metallographic analysis of the fracture revealed secondary, incipient intergranular cracking at the bottom of adjacent dot peen marked lettering. No unusual conditions were observed in the martensitic microstructure of the shaft.

Chemical composition analysis of the input shaft material confirmed the shaft was manufactured from 300M, ultra-high strength, alloy steel. No unusual conditions were observed in the composition.

The high hardness (HRC54) of the 300M shaft makes the component highly notch sensitive with very little ductility. The dot peen marked lettering provided a notch effect and stress riser location for fracture initiation.

Photos